Focusing on CNC precision machining,

——creating quality

Saint-Rich Main production Automobile parts, 5G electronic parts, aviation parts,high-speed rail parts, medical equipment, home appliance smart lock parts, L E D lighting,street light parts, etc.

Successfully completed projects across various sectors.

Provide customer service with exquisite products.

Crafting Quality, Building Trust.

Trusted by:

About Us

One stop parts processing station

At Saint Rich,We mainly provide customers with one-stop service for customized processing and production.

Equipped with 10 automatic tapping and milling machines, 36 drilling and tapping machines, 2 sawing machines, 1 magnetic grinding machine, 4 vibration grinding machines and other post-processing equipment to ensure product accuracy and appearance quality.

Experience Engineers

Modern Technology

Authentic 3D drawing software, enabling teams to deliver

What We Do

Delivering Quality from Start to Finish.

Why Us

Exceptional quality that can’t be beaten.

We take pride in delivering a level of quality that simply can’t be surpassed. Our commitment to excellence is woven into the very fabric of our work, and it’s what distinguishes us from the rest.

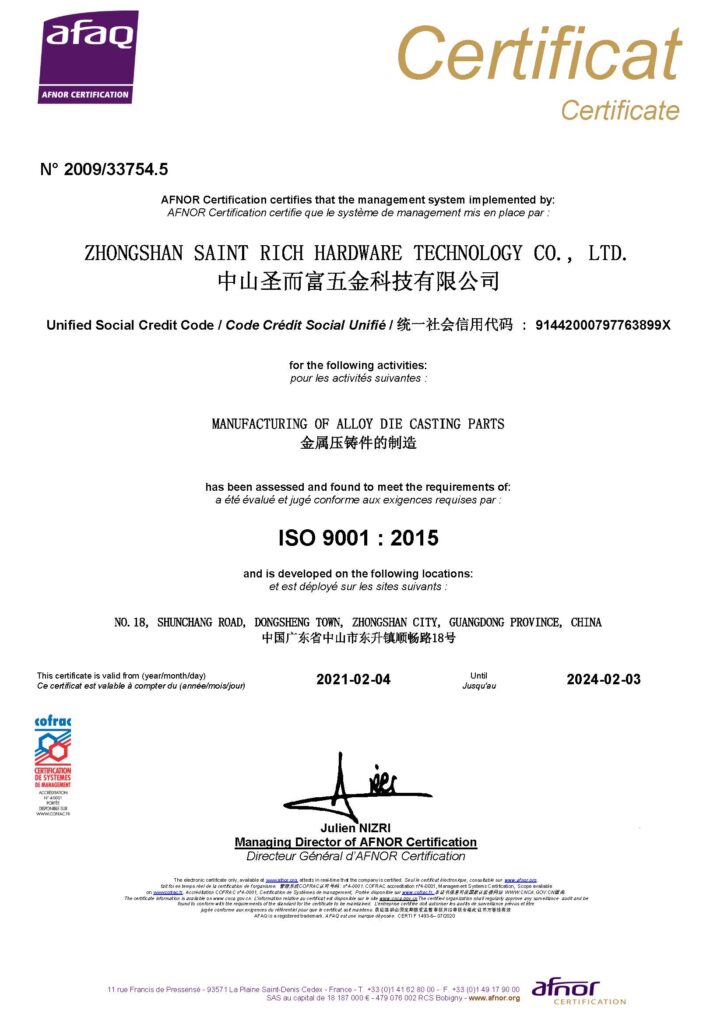

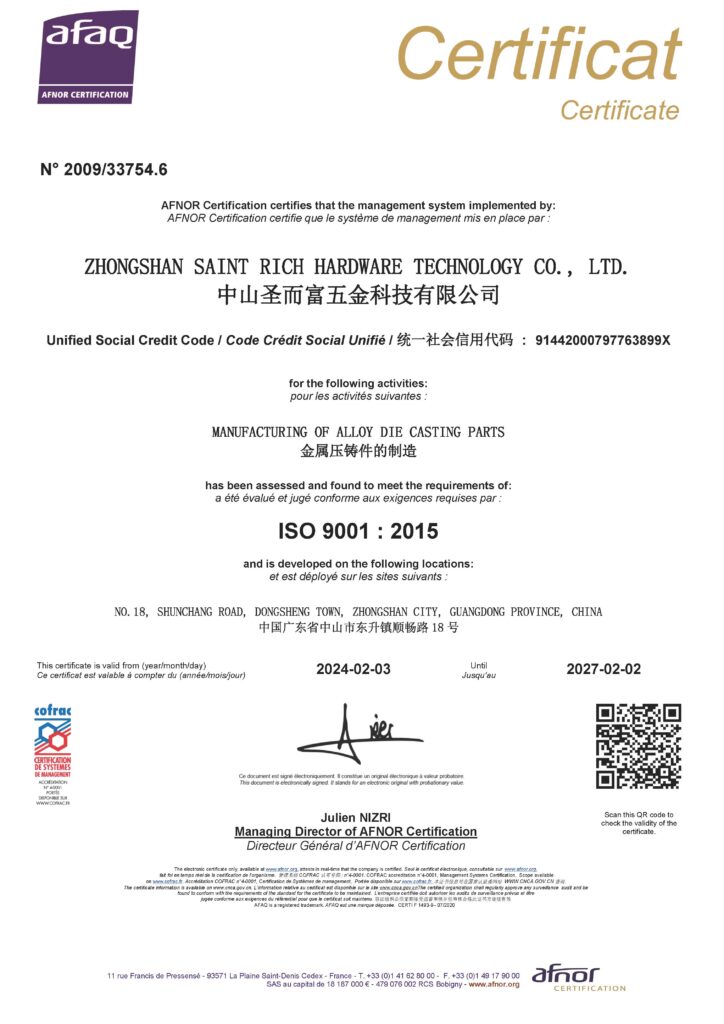

Quality Assurance

We prioritize quality in every aspect of our work, ensuring that your products is built to the highest standards

Expertise

Our team comprises seasoned professionals with years of experience in the machining field.

Our team of skilled professionals has collectively logged 10K hours of dedication to our craft, ensuring that every detail is meticulously executed. We’ve used over 1M tons of top-quality materials, sourced responsibly, to construct high-quality precision products that can withstand inspection.

We believe that actions speak louder than words, and numbers often tell the most compelling story of our success.

Professionals in our team

Years of Experience

Co-operative

Winning Awards

Our Project

Building Dreams, One Project at a Time

Our diverse portfolio spans residential, commercial, and industrial products, each crafted with meticulous attention to detail.

Medical device components

As dental instrument polishing drill bits, cardiac stent delivery system components, surgical instrument components. The materials are mostly medical grade stainless steel and titanium alloy, which require extremely high precision.

Precision Machinery Parts

Such as drone accessories, aircraft accessories, high-speed rail accessories, gears, and shafts. The high precision requirement makes it the main product of CNC machining, widely used in fields such as mechanical equipment.

Automotive components

For example, engine cylinder block, wheel hub, axle components, and couplings. The automotive industry has high requirements for component accuracy and quality, and CNC machining products meet their needs.

Electronic components

For example,high dimensional accuracy, good surface quality, and a balance between aesthetics and functionality are required for components such as phone and computer casings and internal connectors.

How We Work

The Journey of Your Project with Us

Do You Have A Project To Discuss ?

-

Planning and Design

Analyze the processing drawings and clarify the process requirements. Prepare suitable CNC machining equipment, cutting tools, and fixtures, and check if the equipment is in good working condition.

-

Programming and Debugging

Write processing programs according to process requirements and use programming software for simulation. Input the program into the machine and debug it to ensure that the program is correct and error free.

-

Workpiece clamping and tool alignment

Securely clamp the workpiece onto the workbench to ensure accurate positioning. Perform tool alignment operation, determine the relative position between the tool and the workpiece, and set the workpiece coordinate system.

-

Processing and Testing

Start the machine tool and automatically process according to the program. During the processing, timely monitoring is carried out. After the processing is completed, the dimensions and accuracy are measured using inspection tools to ensure compliance.

FAQ

Answers to Your Questions About CNC.

Can’t find the answer you’re looking for? Please contact with our customer service.

CNC precision machining is a manufacturing method that uses computer numerical control technology to perform high-precision machining on parts. By pre programmed instructions, the motion trajectory, speed, feed rate, and other parameters of the machine tool can be controlled to accurately machine.

Aluminum alloy, stainless steel, copper, titanium alloy and other metals, as well as some non-metallic materials such as engineering plastics and ceramics, are all applicable.

Generally, it can reach ± 0.01mm, and some high-end equipment and processes can reach ± 0.001mm. Depending on the equipment and process, the ultra precision machining accuracy can reach micrometer level.

Including material costs, equipment losses, labor costs, and process difficulty, the higher the precision and the more complex the process, the higher the cost.

Depending on the complexity of the parts, precision requirements, batch size, etc., simple parts may take 5-8 days, while complex parts may take several weeks.

By optimizing programming, selecting appropriate tools and cutting parameters, regularly calibrating equipment, and strictly following the testing process to ensure.

Our Blog

Latest Insight & News

Let's Build Something Great Together!

Contact us today, and let the journey to your dream product begin!